Many users of compressed air in segments which needs ISO 8753 class 1 air quality, are still considering Oil-flooded compressors instead of Oil-free compressors. Injecting oil to compress air to seperate it again from the air, is an absurd idea. However, it is still a very common practice. The only reason is because...

20. The history of Screw compressors….

After my article on the service factor used in Screw air-compressors, it is confirmed that there is a lot of misunderstanding and confusion on the topic of Service Factor. Service Factor when it is used and why it is used. Therefor, I like to explain by the history of the Screw...

19. What a compressor manufacturer does not tell you …

When you want to buy a compressor, you will define the flow and the pressure you require for your factory. Then you will check the compressor manufacturer catalogue on which model you will need. Then you compare the kW/HP size of the different manufacturers. What they don't tell you is that : the...

18. Is there no alternative to a centrifugal or Oil-free screw ?

Are there other compressor principles besides the Oilfree-screw and the Centrifugal providing Oil-free Compressed air. The question often is raised, what about Scroll compressor, Water injected compressor, Oil-free industrial compressors and other innovations…? Oil-free Compressed Air can be obtained with other compressor principles but all of them have their application range....

17 What makes the reciprocating technology so popular ?

Recips are being used in many applications and are so widely spread, that one recip is not the other one. First of all, the reciprocating technology is rewarded by the automotive industry as being the best technology when it comes to fuel efficiency ? In the 70ies during the oil...

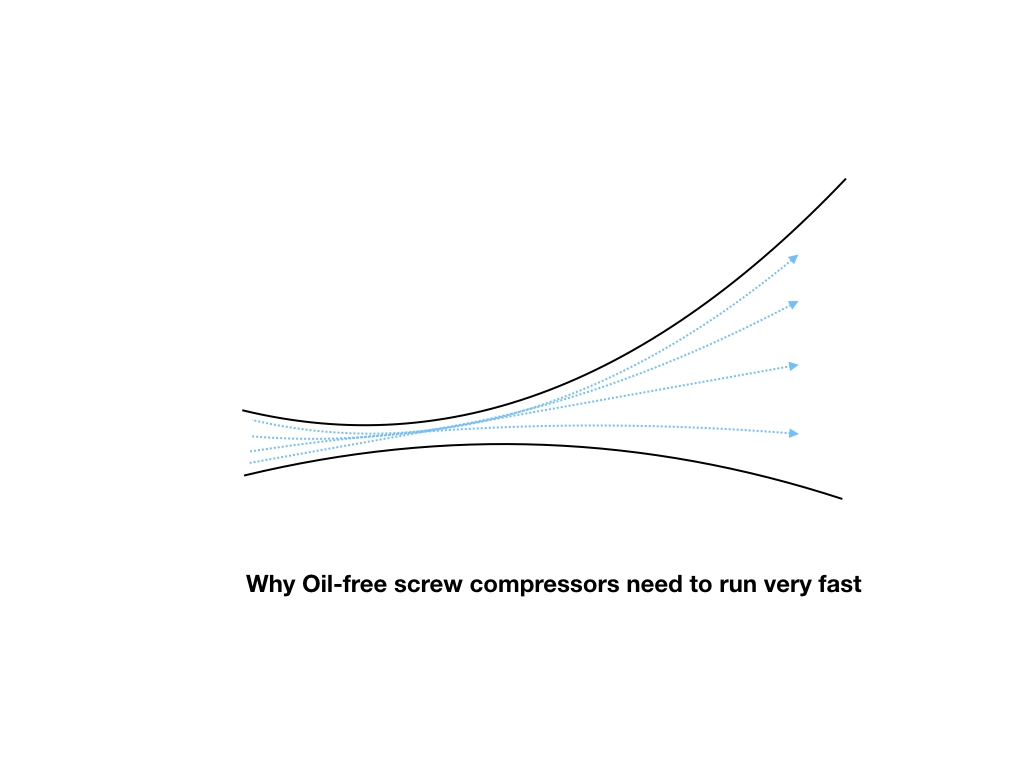

16. Is a dry air-screw compressor a volumetric/displacement compressor ?

A dry screw air-compressor is like a recipricating air-compressor but without segments. If the compression speed is low, most of the air would leak back to the inlet. By running it faster, the time to leak back is shorter. Dry screws are not having any sealant, like other displacement compressors. An oil-flooded screw compressor...

15 .Why test of oil carry over are always done in wintertime !

Technical Oil-free compressed air is defined by the use of an Oil-lubricated air compressor, with an Oil carry over of 2ppm which is than followed by a series of filtration units in order to obtain Class 1 according to ISO8573. Although 2ppm is already a low amount of oil, it...

14. What air-compressor to select the hot and humid countries ?

In regions with high ambient temperatures the choice of a good Oil-free Air-compressor is a challenge. When the temperature outdoor is 50 deg C (122 °F), in the compressor room (if any) the temperature can rise even higher. But even at 40 deg C (104°F), the lifetime of the Oil-free Air...

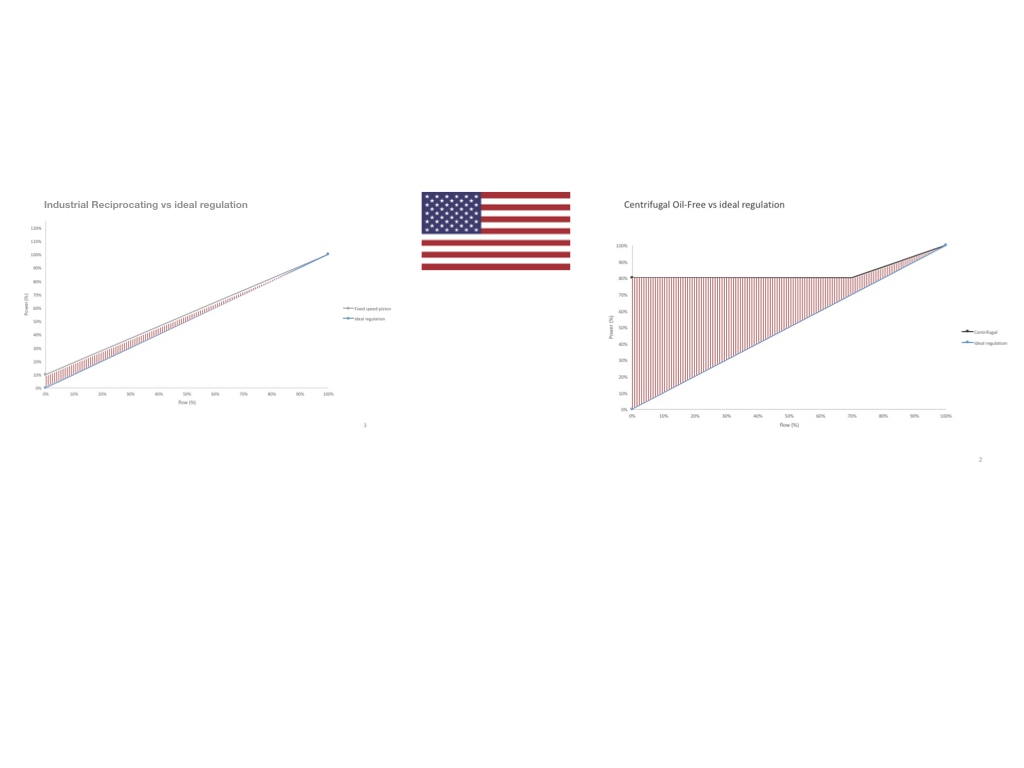

13. Who wins the battle in the N-American market

For Oil-free applications between 100HP and 500 HP at 100-150 PSI, two alternatives for Oil-free air compression are very commonly used, the dry rotaries and the centrifugals. Since the invention of the Oil-free screw compressor, the battle has been between the two technologies. The centrifugals claimed the better efficiency while the Oil-free screw...

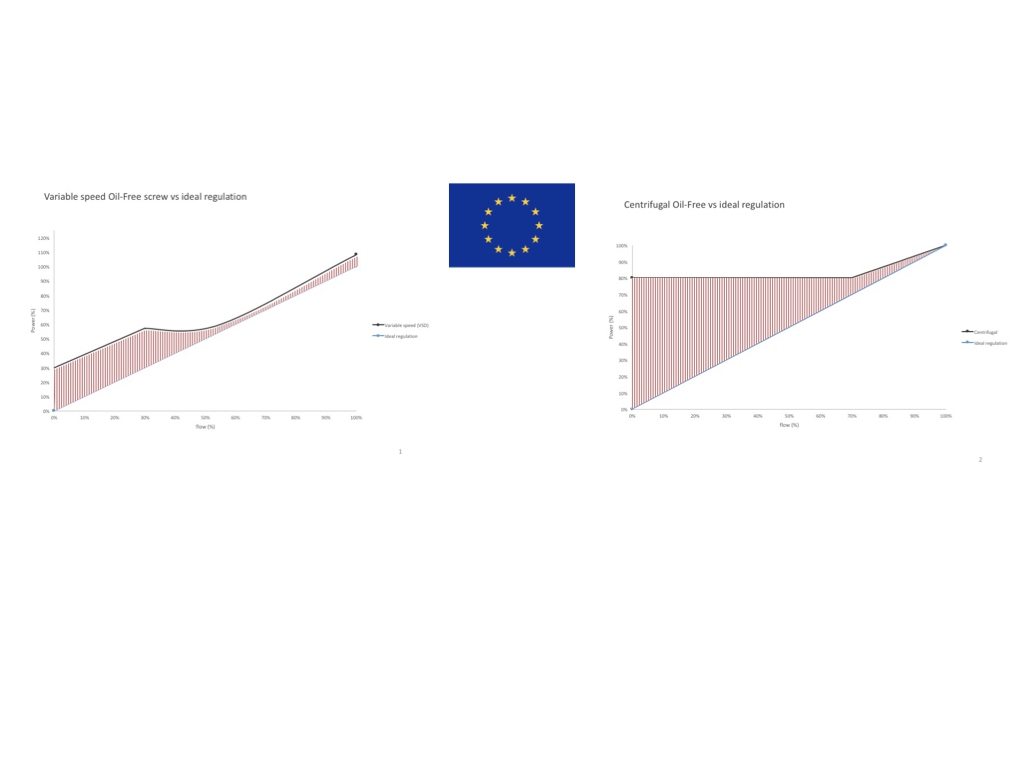

12. Who wins the battle in the European industrial market : Oil free screw vs Centrifugal air-compressor

For Oil-free compressed air applications between 75kW and 355 kW at 7-10 bar, two alternatives for Oil-free compression are very commonly used, the dry rotaries and the centrifugals. Since the invention of the Oil-free screw compressor, the battle has been between the two technologies. The centrifugals claimed the better efficiency while...