Compressed air in a factory can serve two applications. Either it is for a specific application or either it is for the general purpose throughout the whole factory (7-10 bar network). The specific applications often are using different pressure for which they cannot be connected to the general compressed air network at...

10. How should an air-compressor be evaluated ?

An air-compressor is rated by manufacturers at their nominal flow-power level. In the commercial leaflets, the flow and the nominal electrical power is published. The nominal power of an electrical motor can be different than the real power consumed. The nominal power only refers to the frame size of the electrical motor. The flow is measured according...

9. Will there be a DieselGate scandal in the Air-Compressor business ?

In my previous article, I mentioned the upcoming legislation on Air-compressor performances. In the automotive industry, since two years, the Diesel Gate scandal keeps ongoing and despite the focus is on the VW group, it seems that most car manufacturers are trying to escape from it. The unclear or limited specified...

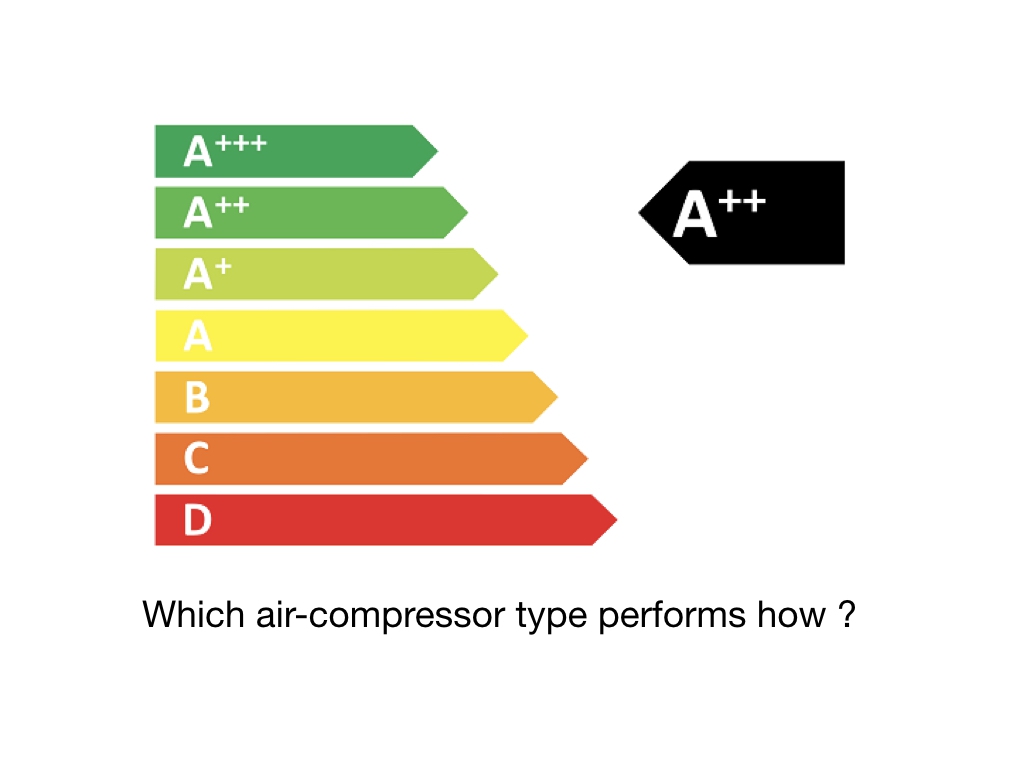

8. Why is there no regulation on Oil-free Compressor performances ?

About 10% of the energy used by the industry is consumed by the compressed air. Depending on the size and the application, it can be an Oil-free compressor or an oil-flooded compressor. The larger size of air-compressors are all Oil-free compressors while the differences in energy efficiency between different compression types are so...

7. Why are twin screw air-compressors so popular ?

In the 19th century, only two types of compression principles were popular, positive displacement, known as piston type, and the centrifugal type. Both were the standard up to the 60ies, but were not reliable enough to keep factories running. The piston compressors were large and required frequently maintenance. The materials and development techniques available in...

6. Why are you still using a track pump to inflate your tire ?

Everybody knows how to inflate the tire of his bike ! Whether you have a simple tourist bike, mountain bike or road bike, all tires have to be inflated to have an efficient ride and to minimize the rolling resistance ! The pressure depends on the type of bike you ride...

5. Does a variable speed compressor really saves energy ?

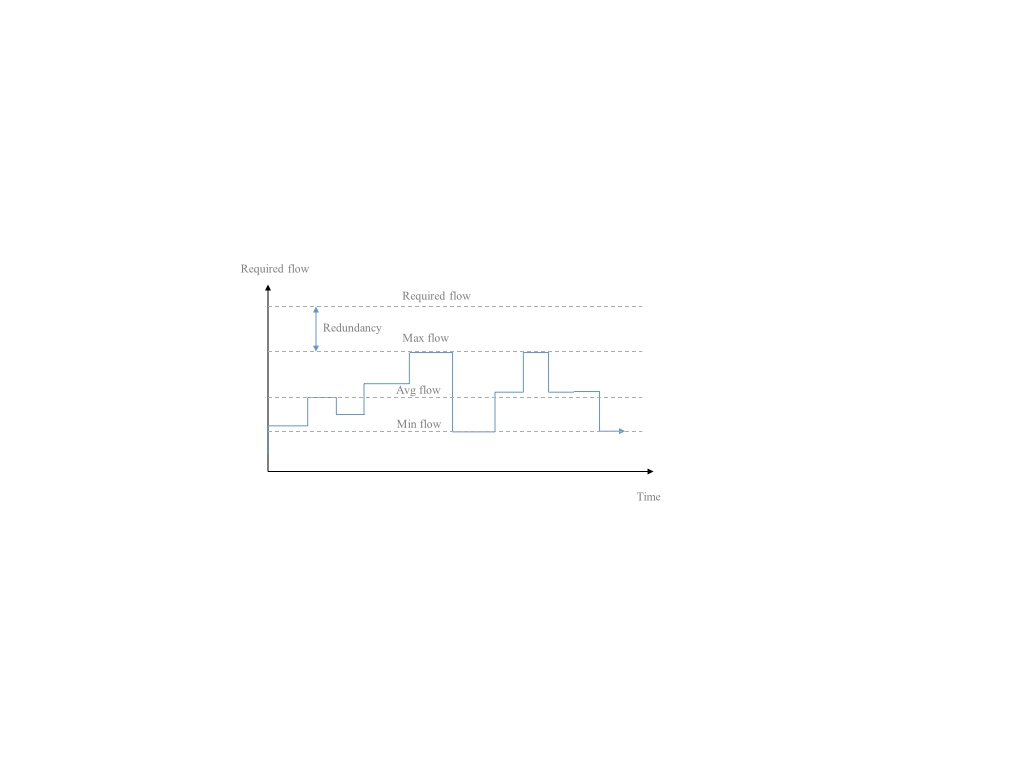

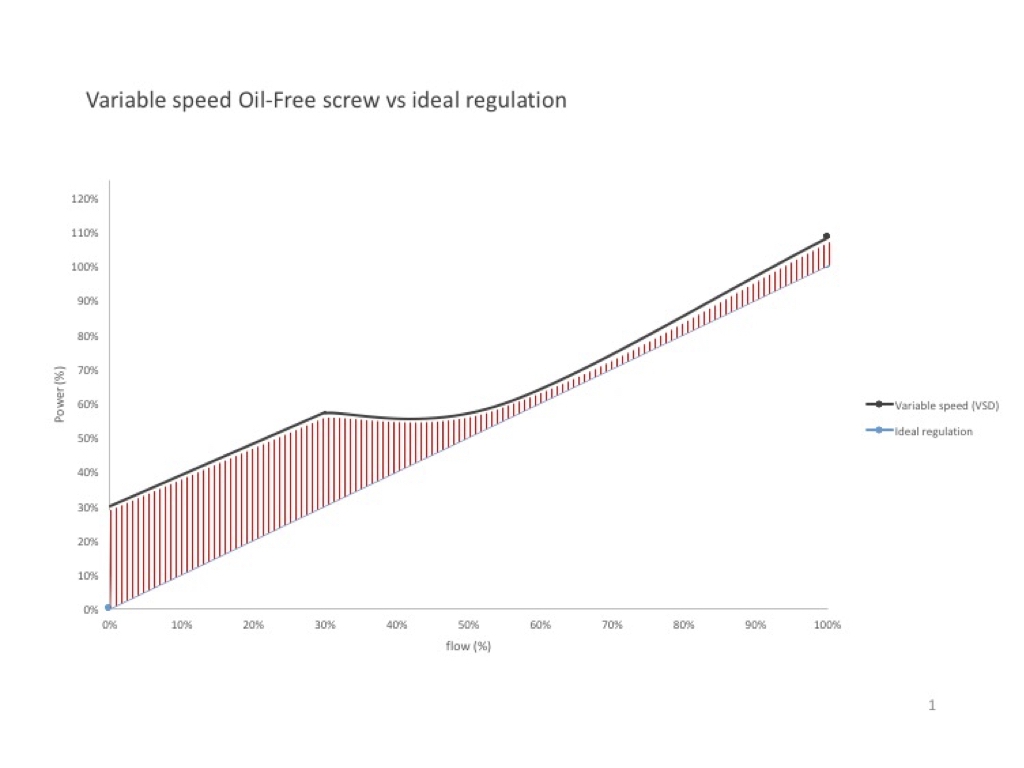

The Variable speed compressors are being promoted as the best solution to energy savings on your compressor ! Is that really true ? Although I have been working on developing the variable speed drive myself, I must admit that it reduces the energy loss rather than save energy ! How comes ? When...

4. Why non-Oil-free compressed air exist at all ?

An Oil-flooded rotary air compressor, compresses air while lots of oil is injected in the compression chamber ! The Oil is used to cool the air, to lubricate the rotors and to seal the compression chamber. Smart one would think. However, the irony is, that it is easy to inject the oil,...

4. Why non-Oil-free compressed air exist at all ?

An Oil-flooded rotary air compressor, compresses air while lots of oil is injected in the compression chamber ! The Oil is used to cool the air, to lubricate the rotors and to seal the compression chamber. Smart one would think. However, the irony is, that it is easy to inject the oil,...

3. Who will choose the new compressor type and why ?

When selecting an Oil-free compressor, the time horizon of the installation is very often near future. The majority of companies buying an Oil-free compressed air installation are large multi-nationals. The management of those large companies have a job rotation of management of every 3-5 yrs. After 3-5 yrs, a new manager, president or...