The comparison of different air-compressors is done on basis of full load air consumption. This is of course an important start to compare different compressor types and brands.

Unfortunately, most compressors are running a lot of time in partial load. Therefore, having a look at partial load is as or even more important.

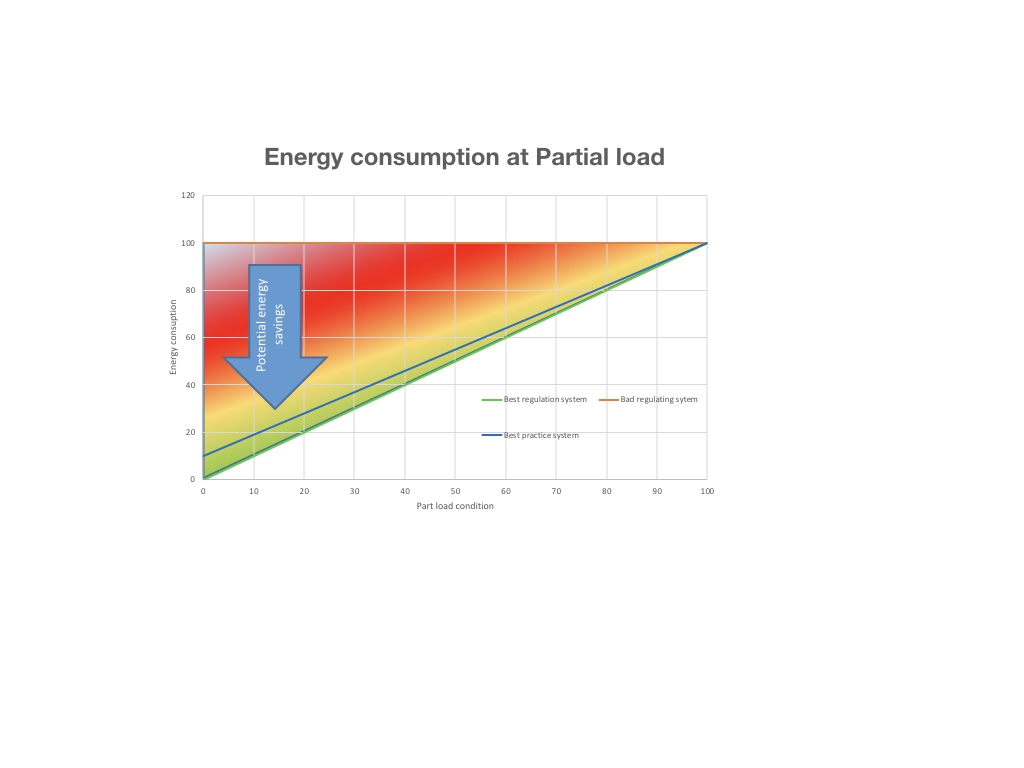

In the graph, the right upper point represents the full load conditions, 100% flow at 100% power. When turn-down is needed, the best regulation would be that the Specific Energy consumption remains constant. This is the green straight line connecting 0% flow at 0% Power with the full load point. Unfortunately, none of the compressors regulate without losses.

The worst regulation would be that the Power consumed remains unchanged during turndown. The power consumed during turndown remains constant. This could be obtained when the full flow would be blown off. This is shown by the red horizontal line.

The closer to the green line, the more efficient the air-compressor will operate in partial load.

Most compressors are regulated in between. A centrifugal compressor with a turndown lower than 75% often blows off, and remains in the red zone. Oil flooded remain high due to the high back pressure in the Oil-separator. Oil-free screw start loosing the internal coating to guarantee a good volumetric efficiency.

The Blue line, represents the best practice with very little losses and easy to regulate downwards to zero flow.

Which would be the best practice in partial load ?

#energy#oil-free compressed air