For Oil-free compressed air applications between 75kW and 355 kW at 7-10 bar, two alternatives for Oil-free compression are very commonly used, the dry rotaries and the centrifugals.

Since the invention of the Oil-free screw compressor, the battle has been between the two technologies. The centrifugals claimed the better efficiency while the Oil-free screw claims the better partial-load.

Below 200 kW, the Oil-free screw claims even a higher efficiency than the Turbo compressor.

The efficiency of the centrifugal air compressor depends a lot on the design and ambient conditions, at which the compressor has to run. Continuous development using CFD and Finite Elements calculation techniques, allows to improve further the performance of the cores for the centrifugals.

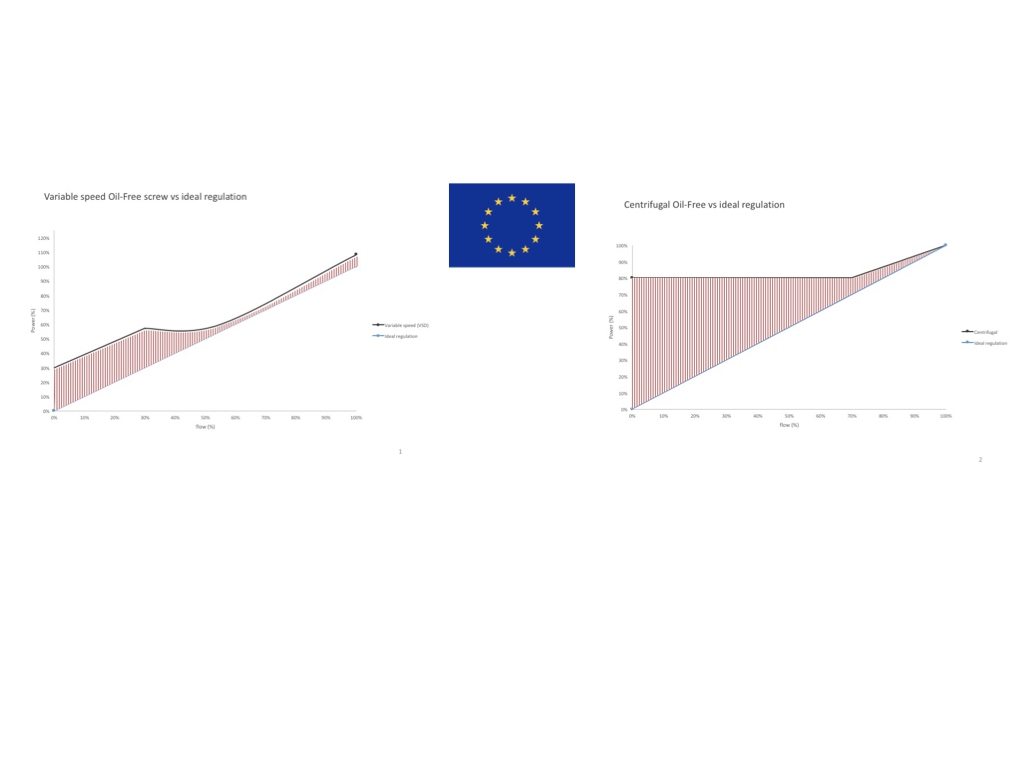

The Oil-free screw compressor has claimed its marketshare thanks to the better partial load conditions, rather than the better full load efficiency. The partial load condition of the centrifugal is poor ! Despite a regulation possibility of 30-35% downwards before hitting the surge line, specific power consumption at partial load is also increasing, similar to an Oil-free screw compressor.

Since the 80ies, the centrifugals have lost the battle and the Oil-free twin screw gained a lot of marketshare in Europe. The home base for the Dry rotaries is Europe while for centrifugals it is North-America.

Today a reverse trend is ongoing towards centrifugals in the hope to reduce operational costs.

Do you observe the same trend in your country ?