The topic of the Variable speed drive is an interesting topic as so much publicity is being made. Energy saving is the slogan.

Yes, when selecting an Oil-flooded air-compressor, you should in most cases select a VSD !

Why ?

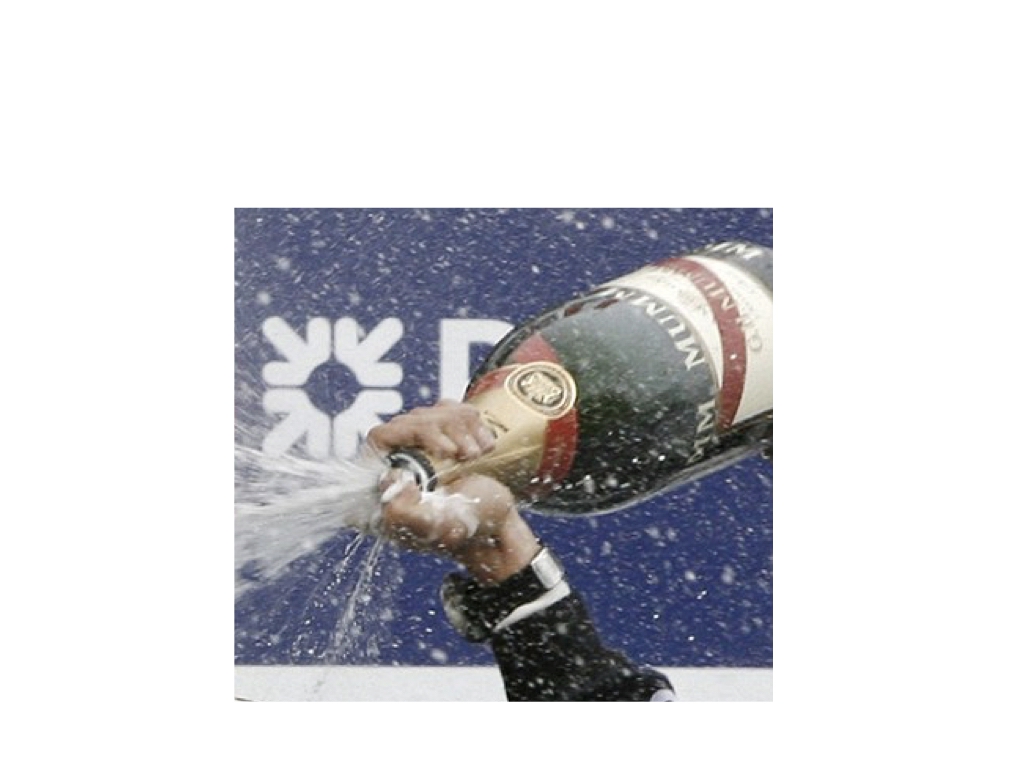

Because the power absorbed at unload can reach very high levels like 80% of total power at 50% of max flow. The reason why this is so high, is that the Oil-seperator in the Oil-flooded compressor is like a bottle of Champagne. You shake it and open the bottle. When the cork is released, a fountain of tasteful Champagne is wasted. Useful in the formula 1 celebrations but less useful if the oil leaves the Oil-seperator with dramatic consequences.

To reduce the huge energy loss in partial load, a VSD is needed for an Oil-flooded air-compressor.

The better solution is to invest in an Oil-free compressor with low losses at partial load, like Centrifugals and Industrial Recips. Better energy efficiency and less waste produced