To compress air, two compression principles are defined, either volumetric compression either dynamic compression.

To compress air, two compression principles are defined, either volumetric compression either dynamic compression.The Volumetric compression reduces a volume to a smaller volume, and the ratio of the two volumes defines the compression ratio. This is the working principle of a reciprocating air-compressor. During compression, the compressor chamber is sealed of by the piston rings and the in and outlet valves.

In a Dynamic compression, the air is accelerated to a higher speed. In a diffuser, the speed of the air is brought to a lower speed which increase the pressure. The speed of the air, avoid the air to leak back to the inlet. This is the working principle of centrifugal air-compressor.

In a screw compressor, two types exists. The oil-lubricated and the Oil-free screw compressor.

The Oil-lubricated screw compressor, the oilfilm between the screws profiles, is sealing of thee compression chamber. The shape of the screws will close of the inlet during the compression. This can be considered as a volumetric compression.

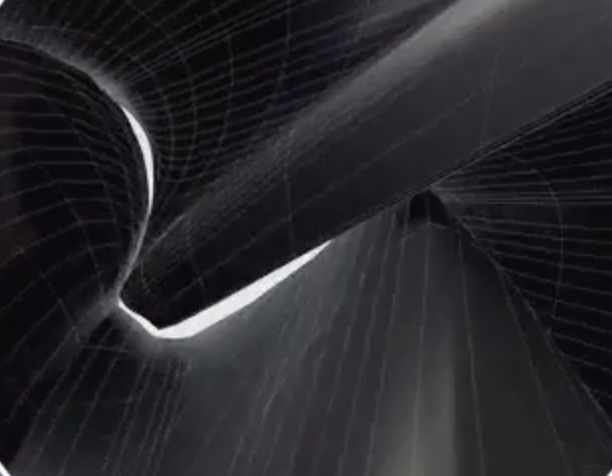

In an Oil-free screw compressor, no oil is injected and thus no sealing of the air-gap is happening.

Therefor, the leakage back to the inlet is substantial. The volumetric efficiency of an Oil-free screw air-compressor would be very low, if it would run at a low speed. To reduce the air-leakage, the speed of the Oil-free screw rotors are substantially increased. The compression of the air uses two principles, the volumetric compression and the dynamic principle. We could call this a Semi volumetric-Semi dynamic compression ?

Does it makes sense to regulate the speed downwards to safe energy at partload for a Semi volumetric-Semi dynamic compression ?