For Oil-free applications between 100HP and 500 HP at 100-150 PSI, two alternatives for Oil-free air compression are very commonly used, the dry rotaries and the centrifugals.

Since the invention of the Oil-free screw compressor, the battle has been between the two technologies. The centrifugals claimed the better efficiency while the Oil-free screw claims the better partial-load.

Below 300HP, the Oil-free screw claims even a higher efficiency than the Turbo compressor.

The energy efficiency of the centrifugal depends a lot on the design of the aero's and ambient conditions, at which the compressor has to run. Continuous development using CFD techniques and Finite Elements, allows to improve further the performance of the cores for the centrifugals.

The North-American market has been dominated by centrifugals for air-compression. Major US manufacturers are/were offering competitive designs. Over time, numerous merger and acquisitions have occured.

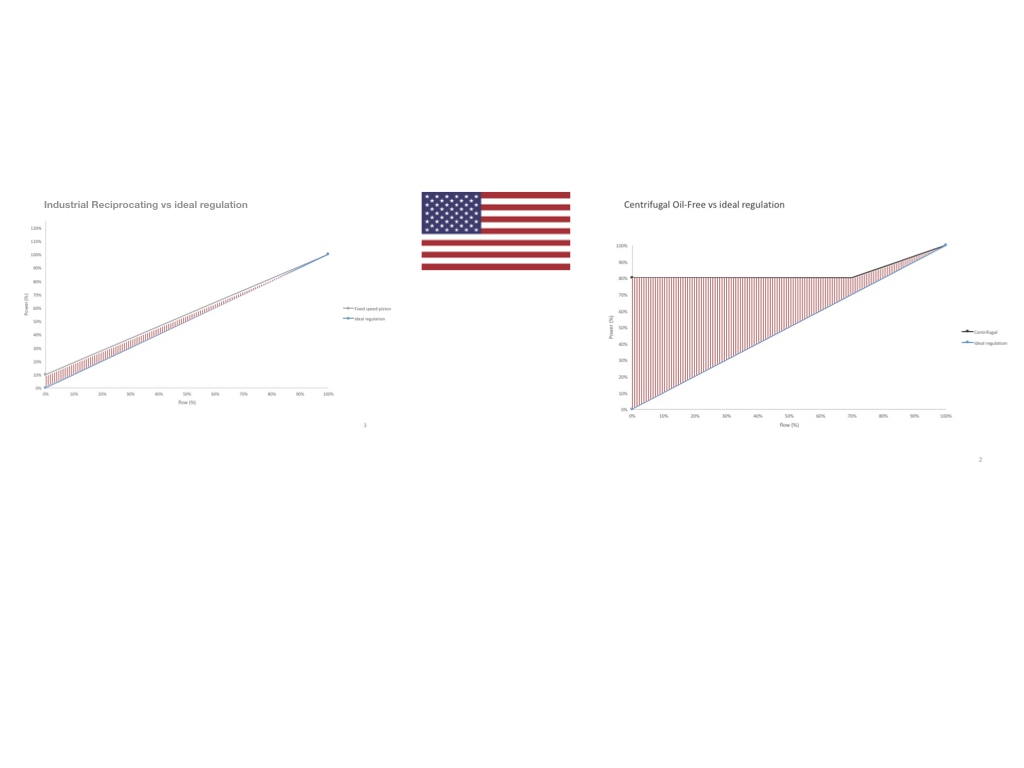

The Dry screw has penetrated into the US market and pushed back the centrifugals as they are not that efficient at part-load.

A third type of Oil-free compression is available on the US market for Oil-free compression which is the Oil-free reciprocating compressors. They are lndustrial reciprocating air-compressors which have superior energy efficiency and can operate in very difficult ambient conditions. When long-life time, durability and high efficiency is required, the savings outperform the additional investment.

Will the US remain dominated by the centrifugals ?